| |

|

|

| |

|

| |

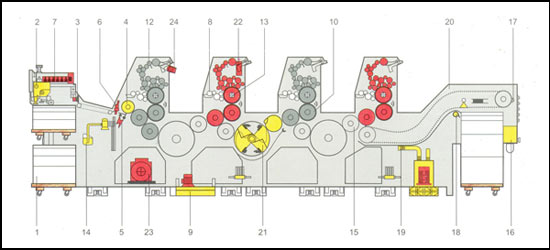

| DELTA |

DELTA |

DELTA |

DELTA |

DELTA |

| 661 |

662 |

662 |

664 |

665 |

| with low |

with low |

with high |

with low |

with low |

| pile |

pile |

pile |

pile |

pile |

| delivery |

delivery |

delivery |

delivery |

delivery |

|

| |

| Maximum sheet size |

485 × 660 mm |

485 × 660 mm |

|

485 × 660 mm |

485 × 660 mm |

| Maximum sheet size |

290 × 310 mm |

290 × 310 mm |

|

330 × 310 mm |

330 × 310 mm |

| - with perfecting facility |

|

330 × 310 mm |

|

330 × 310 mm |

330 × 310 mm |

| Maximum printing area |

475 × 650 mm |

475 × 650 mm |

|

475 × 650 mm |

475 × 650 mm |

| Max. paper thickness |

0.45 mm |

0.45 mm |

|

0.45 mm |

0.45 mm |

| Pile height in feeder |

980 mm |

980 mm |

|

980 mm |

980 mm |

| Pile height on delivery |

460 mm |

460 mm |

820 mm |

820 mm |

820 mm |

| Offset plate size |

0.3 ×530 × 650 mm |

0.3 ×530 × 650 mm |

|

0.3 ×530 × 650 mm |

0.3 ×530 × 650 mm |

| Blanket size |

1.9 ×560 × 664 mm |

1.9 ×560 × 664 mm |

|

1.9 ×560 × 664 mm |

1.9 ×560 × 664 mm |

| Max. printing speed |

10,000 i.p.h. |

10,000 i.p.h. |

|

10,000 i.p.h. |

10,000 i.p.h. |

| Min. printing speed |

3,000 i.p.h. |

3,000 i.p.h. |

|

3,000 i.p.h. |

3,000 i.p.h. |

|

|

|

|

|

| Requirement of Electric motors |

|

| - Main deriver |

2.2 kw |

2.2 kw |

7.5 kw |

7.5 kw |

| - Compressor |

3.0 kw |

3.0 kw |

3.0 kw |

3.0 kw |

| - Feeder |

0.37 kw |

0.37 kw |

0.37 kw |

0.37 kw |

| - Anti set-off powder Spray |

0.25 kw |

0.25 kw |

0.25 kw |

0.25 kw |

|

|

| Dimensions of machines |

| - Length |

2,100 mm |

2,950 mm |

3,950 mm |

5,650 mm |

6500 mm |

| - Width (Inc. Walkways) |

2,250 mm |

2,250 mm |

|

2,250 mm |

2250 mm |

| - Height |

1,700 mm |

1,700 mm |

|

1,700 mm |

1700 mm |

|

| |

| Weight of machine |

2,350 kg. |

3,700 kg. |

4,350 kg. |

7,300 kg. |

8,700 kg. |

|

| |

| Features |

|

|

| |

| |

|

DELTA 661 |

DELTA 662 |

DELTA 664 |

DELTA 665 |

| 1 |

Pre - Loaded Feeder |

S |

S |

S |

S |

| 2 |

Feeder Head : One - System Feeder Head

Two - System Feeder Head |

S |

S |

S |

S |

| O |

O |

O |

O |

| 3 |

Double Sheet Detector |

S |

S |

S |

S |

| 4 |

Rotary Gripper Infeed System |

S |

S |

S |

S |

| 5 |

Automatic Impression Engagement and Disengagement |

S |

S |

S |

S |

| 6 |

Front & Side Lays Micro Adjustments On The Run |

S |

S |

S |

S |

| 7 |

LED Monitoring Display |

S |

S |

S |

S |

| 8 |

Film Dampening |

- |

- |

S |

S |

| 9 |

Recirculating Water Pump system |

- |

S |

S |

S |

| 10 |

Bearer To Bearer Contact Between Plate and Blanket Cylinder |

S |

S |

S |

S |

| 11 |

Quick Action Plate Clamps |

S |

S |

S |

S |

| 12 |

Powerful 19 - Roller Ink Train |

S |

S |

S |

S |

| 13 |

Micro Adjustment of Circumferential and Lateral Running Register |

- |

S |

S |

S |

| 14 |

Central Lubrication Systems |

S |

S |

S |

S |

| 15 |

Specially Treated Cylinder To Prevent Setting Off |

- |

S |

S |

S |

| 16 |

Powder Spray Unit |

S |

S |

S |

S |

| 17 |

Delivery Jam Detector |

S |

S |

S |

S |

| 18 |

Powerful Vacuum Brake |

S |

S |

S |

S |

| 19 |

Sheet Decurler |

O |

S |

S |

S |

| 20 |

Delivery : Low Pile

High Pile |

S |

S |

S |

S |

| - |

O |

O |

O |

| 21 |

Quick Change Perfecting Unit |

- |

O |

O |

O |

| 22 |

LED Changer over Display |

- |

O |

O |

O |

| 23 |

AC Main Drive with Controller |

S |

S |

S |

S |

| 24 |

Remote Control of Inking Unit and Register |

- |

O |

O |

O |

| 25 |

PROTOCOL / BACHER Pre-register System |

- |

O |

O |

O |

| 26 |

Alcohol Dampening |

O |

O |

O |

O |

| 27 |

Additional Roller for Inking Unit |

O |

O |

O |

O |

| 28 |

GE FANUC Freely Programmable Control System |

- |

- |

O |

O |

| 29 |

Non-stop Delivery |

O |

O |

O |

O |

| 30 |

NPI Attachment |

O |

O |

O |

O |

|

| |

|

| [ S : STANDARD ] [ O : OPTIONAL ] |

|

|

| |

| |

|

|

|

| |

|

|

|

|